How Do You Know Where Tge Check Balls in a Valve Body Go Back at?

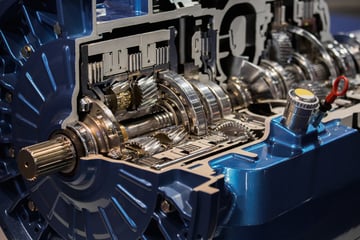

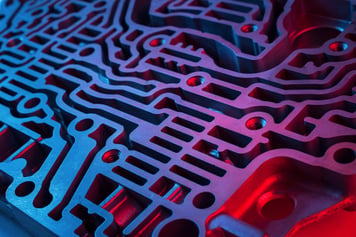

As with any automotive service, it tin can be like shooting fish in a barrel to focus on the principal components of your transmission rebuild jobs, but don't forget to evaluate the power of the pocket-size components, as well. In this mail, we'll explain how the smallest parts in your transmission rebuild kit make the biggest difference and why you should accept the fourth dimension to bank check them for quality. Depending on the awarding yous're working on, the type of transmission, and other service factors, the smallest parts in your rebuild kit may vary from vehicle to vehicle. However, most rebuild kits incorporate most if non all of the following small components that can significantly affect the performance of the unabridged transmission. Inside the valve body of the transmission, there are different types of valves that direct fluid through the unit of measurement. 1 of those valves designs utilize a bank check ball, which allows or blocks fluid flow. Fluid pressure causes a check ball that sits in a pocket to block and unblock on orifice that fluid is flowing through or trying to flow through. This controls the timing and redirection of fluid flow. While the office of a check brawl may seem adequately simple, a huge difference in quality exists depending on what fabric a check ball is fabricated of. Steel check balls are decumbent to damaging the seats in the separator plate, causing incomplete sealing of the orifice in the plate over time. This can crusade multiple problems, such as shifting issues, timing issues, and more depending on the affected oil circuit.On the other manus, elastomer or rubber check balls themselves wear down over fourth dimension, resulting in poor fit to the orifices in the plate or, in extreme cases, consummate blow through of the check ball through the orifice in the plate. In gild to protect the check brawl seats and ensure proper sealing, look for torlon bank check balls in your rebuild kits. Torlon is a loftier-performance thermoplastic that are formed and then hardened to resist high temperatures. The textile is too highly touch resistant and is durable enough to last across the length of the rebuild. Transmission filters inside applications are disquisitional to the operation of a vehicle in general. The office of a filter is to act as a sieve to remove clay, droppings, and contaminants from fluid as it moves through the system. Because fluid travels throughout the transmission and is responsible for a variety of functions, the quality of the fluid itself affects the unabridged system'south operation. If your transmission filters fail, dirty fluid will contaminate the unit and can pb to a lack of hydraulic power. Some pocket-sized filters that are extremely important to overall transmission performance are the valve body strainers. These small screens inside the valve body perform the role of a filter by minimizing the corporeality of small-scale particles that enter oil circuits, affecting spool valves and solenoids. Afterward a clean flush, replacing valve torso strainers during a rebuild helps to proceed debris and contaminants from hindering the transmission's performance. The o-rings in your rebuild kit must be replaced during every reassembly, but it'due south also disquisitional to monitor the quality of these small-scale components. O-rings made of loftier performance materials (either the same as the OE components or meliorate) will elongate the life of the rebuild and prevent comebacks to your shops in the outcome of transmission failure. In club for a manual rebuild to perform to its highest potential (and if you're using the right parts, that should be the same potential every bit a new unit of measurement), every office has to meet a sure standard of quality, large or small. While we simply listed a few examples here, you should recognize that all the of the pocket-size components matter. If the small parts tin can't do their job, information technology leads to bigger and bigger problems for the unit as a whole. When it comes to what'southward inside your rebuild kits, materials and blueprint actually practice make all the difference, as well equally having every unmarried component you lot need for a consummate rebuild. Skimping on quality or even emitting small parts all together are the style that low-quality kits cut costs, merely those strategies come at the risk of your rebuild's success. Instead, find a true quality overhaul kit you can depend on. What'southward actually critical for store owners, technicians, and even drivers to sympathise is that information technology's truly never worth it to overlook the modest details in gild to get the service washed speedily or cheaply. In gild to provide the best rebuild service your shop is capable of, you must commit to putting attending and care into every function of the process — and that includes the little details.  Looking at the large motion picture is certainly important when information technology comes to your transmission rebuilds -- the awarding, the diagnosis, and the rebuild process itself. Merely getting the modest details correct matters just equally much, if non more, to the success of the service. In fact, the smallest parts you find inside your rebuild kit, no matter what type you use, tin mean the difference between a satisfied customer and a improvement. When attending to detail is a trait that tin can gear up your business apart from your competitors, yous can't afford to let the small parts slide.

Looking at the large motion picture is certainly important when information technology comes to your transmission rebuilds -- the awarding, the diagnosis, and the rebuild process itself. Merely getting the modest details correct matters just equally much, if non more, to the success of the service. In fact, the smallest parts you find inside your rebuild kit, no matter what type you use, tin mean the difference between a satisfied customer and a improvement. When attending to detail is a trait that tin can gear up your business apart from your competitors, yous can't afford to let the small parts slide.Small Rebuild Parts That Affair

Torlon Check Balls

Valve Body Strainers

O-Rings

Perhaps the smallest rebuild components are the o-rings. The purpose of o-rings in a transmission application are to seal the unit against any leaks. These elastomer gaskets are shaped like a loop and are seated in a groove. They're designed for compression between 2 or more parts during the assembly (or in the case of a rebuild, the reassembly) of the unit of measurement, creating a consummate, tight seal at the interface.In transmission applications, o-rings keep fluid and/or air from both escaping and entering the wrong oil channels, valves, or assemblies, especially at high pressure level joints that are prone to leakage.

Perhaps the smallest rebuild components are the o-rings. The purpose of o-rings in a transmission application are to seal the unit against any leaks. These elastomer gaskets are shaped like a loop and are seated in a groove. They're designed for compression between 2 or more parts during the assembly (or in the case of a rebuild, the reassembly) of the unit of measurement, creating a consummate, tight seal at the interface.In transmission applications, o-rings keep fluid and/or air from both escaping and entering the wrong oil channels, valves, or assemblies, especially at high pressure level joints that are prone to leakage. Transmission Rebuild Quality Comes Down to the Details

Source: https://blog.transtec.com/how-the-smallest-parts-in-your-transmission-rebuild-kit-make-the-biggest-difference

0 Response to "How Do You Know Where Tge Check Balls in a Valve Body Go Back at?"

Post a Comment